Digitopia Holographic LED Screen: High-Transparency Displays with S...

In a world where immersive experiences are redefining how brands engage audiences, Digitopia’s Holographic LED Screen stands out...

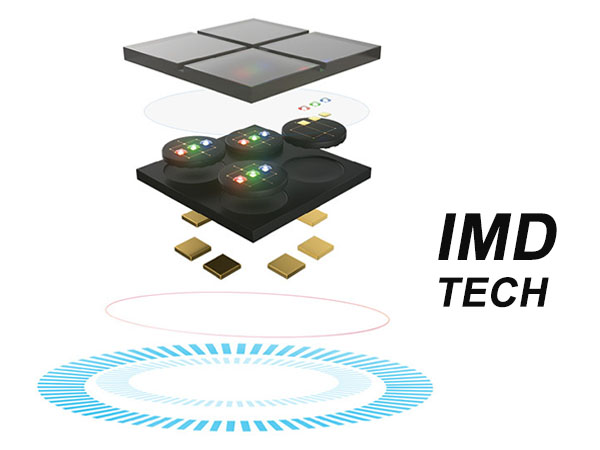

As LED display technology continues to evolve, the demand for fine pixel pitch solutions is driving innovations in packaging. Among the most promising advancements is IMD (Integrated Matrix Device) LED technology, also known as the “four-in-one” package.

IMD LED displays combine the strengths of COB (Chip on Board) and SMD (Surface Mounted Device) technologies while reducing many of their weaknesses. This makes IMD a balanced, cost-effective, and reliable choice for applications requiring smaller pixel pitches and high visual performance.

What is IMD LED Technology?

IMD (Integrated Matrix Device) packages four basic pixel structures into a single encapsulated unit. Each unit contains 12 RGB LED chips arranged in a compact, integrated design.

This structure addresses several long-standing challenges in LED displays:

In essence, IMD represents the next step in packaging technology, bridging the gap between COB’s integration and SMD’s flexibility.

Key Advantages of IMD LED Displays

1. Superior Uniformity and Stability

Compared to COB, IMD displays offer more consistent brightness and color uniformity across the screen. This makes them ideal for environments where image fidelity and detail clarity are critical.

2. Enhanced Impact Resistance

Conventional SMD LEDs are prone to lamp drop-offs, especially in rental and event setups. IMD modules, however, feature four times more soldering pads per light, making them significantly more resistant to physical impacts.

3. Simplified Maintenance

Unlike COB, where damaged LEDs are difficult to repair individually, IMD allows for single-light repairs. This reduces downtime, cuts maintenance costs, and ensures consistency in both appearance and performance.

4. Production Efficiency

IMD uses the same manufacturing lines as traditional SMDs (e.g., 1010 lines), meaning no large investments in new equipment are needed. Its four-in-one structure also requires fewer solder joints, lowering the risk of poor connections.

Production is faster as well — IMD requires one placement action instead of four, greatly improving throughput and lowering assembly costs.

Limitations of IMD LED Displays

Despite its advantages, IMD is not a perfect solution. Some challenges include:

IMD vs COB vs SMD: Finding the Balance

Why IMD is the Wiser Choice for Fine-Pitch Applications

For industries demanding high-resolution, durable, and cost-effective LED displays — such as command centers, broadcast studios, corporate experience centers, and premium retail — IMD provides the best balance.

It is not the cheapest technology, nor is it flawless, but its combination of robustness, ease of maintenance, and uniform visual performance makes it a strategic choice for the future of fine-pitch LED display applications.

📞 To explore IMD LED solutions for your brand, call +91 7799000590 / +91 7799000600

📧 Email: [email protected]

Digitopia™ by Ebani Tech

Pioneering smarter LED technologies for the next generation of display applications.

In a world where immersive experiences are redefining how brands engage audiences, Digitopia’s Holographic LED Screen stands out...

Modern museums are more than spaces to preserve history — they are cultural landmarks that blend architecture, storytelling,...

As technology continues to evolve, LED displays have become one of the most powerful tools for advertising, branding,...